-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

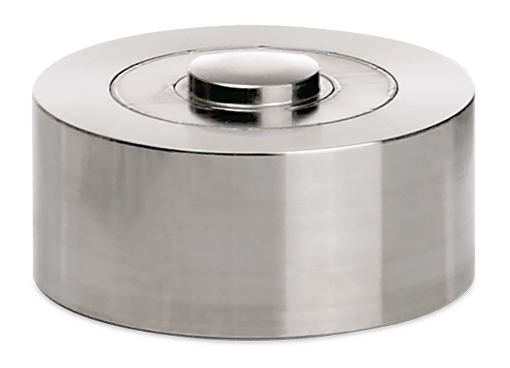

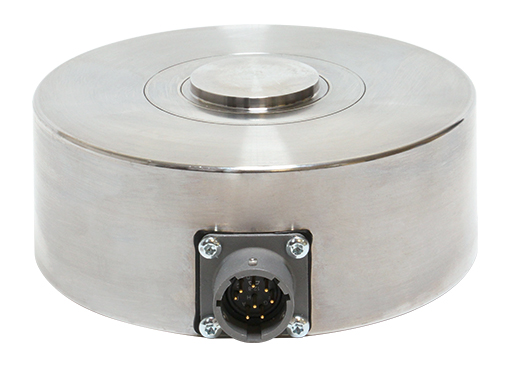

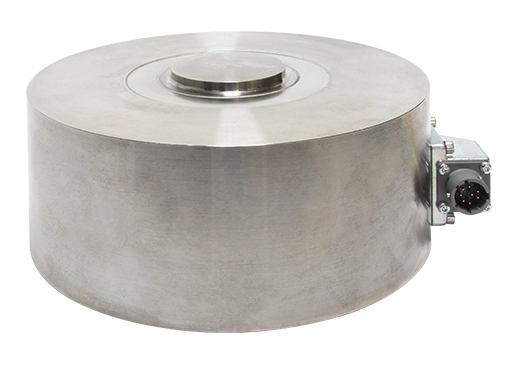

8526 Compression load cell

Compact, robust, high performance, for restricted spaces, for static and dynamic measurements, welded construction, protection class IP64, stainless steel

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- Measuring ranges from 0 ... 100 N to 0 ... 1 MN

- Extremely compact design

- For static and dynamic measurements

- Three threaded holes on bottom for easy mounting and cable suitable for drag chain application

- Protection class IP64

- Relative non-linearity: ≤ ±0.1 % F.S.

- Standardized output signal

- burster TEDS optionally available

-

Product data

Model 8526 Measuring range 0 … 100 N

0 … 200 N

0 … 500 N

0 … 1 kN

0 … 2 kN

0 … 5 kN

0 … 10 kN

0 … 20 kN

0 … 50 kN

0 … 100 kN

0 … 200 kN

0 ... 500 kN

0 ... 1 MNDirection of force Compression Standardization Yes Signal output 1 mV/V Protection class IP64 Overload protection No Pull-plate No Load introduction button Yes Range of operating temperature -30 ... +80 °C Specific characteristics - Measuring ranges from 0 ... 100 N to 0 ... 1 MN

- Extremely compact design

- For static and dynamic measurements

- Three threaded holes on bottom for easy mounting and cable suitable for drag chain application

- Protection class IP64

- Non-linearity from 0.1% F.S.

- Standardized output signal

- burster TEDS optionally available

-

Description

Thanks to its compact shape and three fixing holes on its underside, the 8526 compression load cell can be used in a variety of applications. With its wide choice of measuring ranges from 0 ... 100 N up to 0 ... 1 MN, it really can cover a wealth of measurement tasks, from the laboratory to use in heavy industry.

The integral load button provides an easy and reliable means of applying the force to be measured. Angle errors in the load application with a deviation from the measurement axis of up to 3° have only a minor influence on the measurement signal. For ideal measurement accuracy, the load cell should be mounted on a surface that has been ground and has a hardness of at least 60 HRC.

The model 8526 load cell is designed with an internal elastic membrane, to which strain gages are attached. When a compressive load is applied to the load cell, the membrane is elastically deformed and transfers its tension to the strain gages. These in turn respond with a proportional change in their ohmic resistance, which can be evaluated using a suitable instrumentation amplifier or display device.

-

Data Sheet & Downloads

-

Videos

Please accept marketing-cookies to watch this video.Monitoring the crimping process of rotational symmetrical parts

Please accept marketing-cookies to watch this video.Example showing load cell fitted under pre-load with extreme overload protection

Please accept marketing-cookies to watch this video.

-

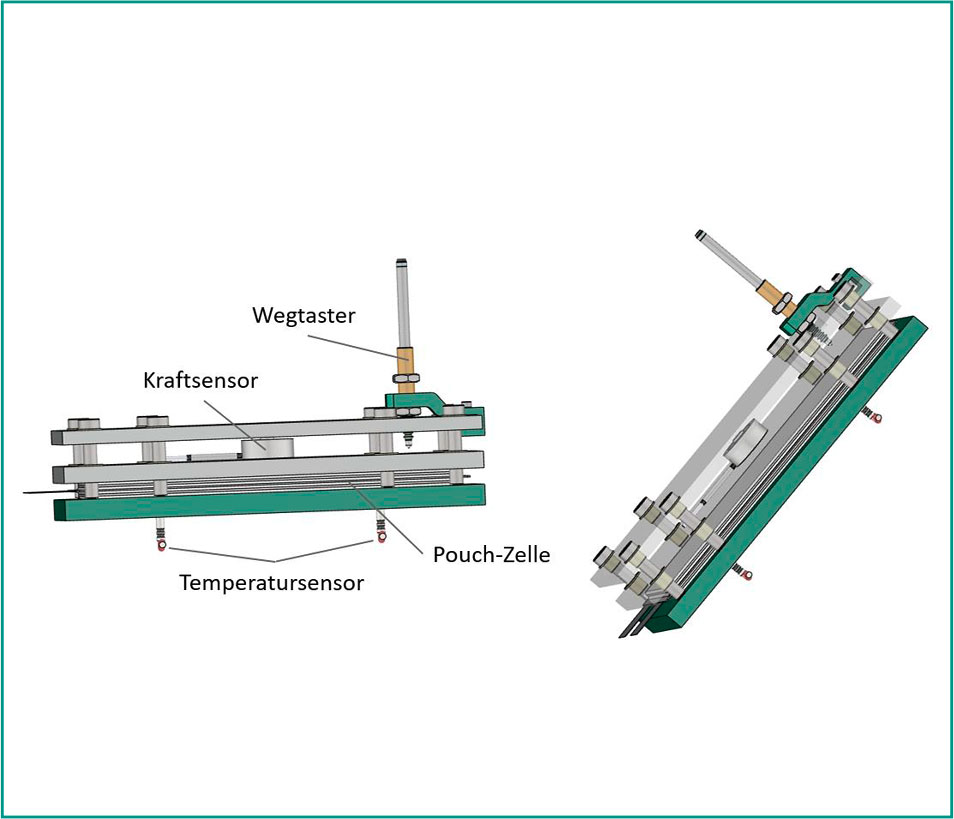

Application Examples

Related products

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.