-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

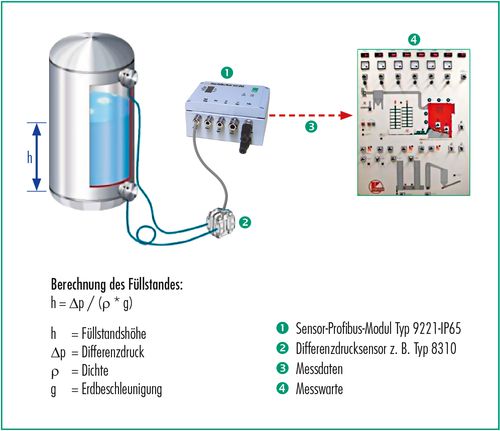

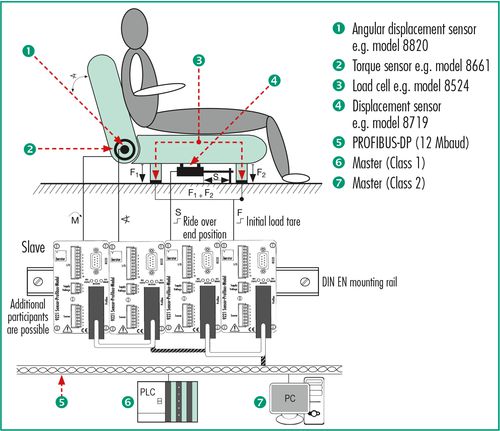

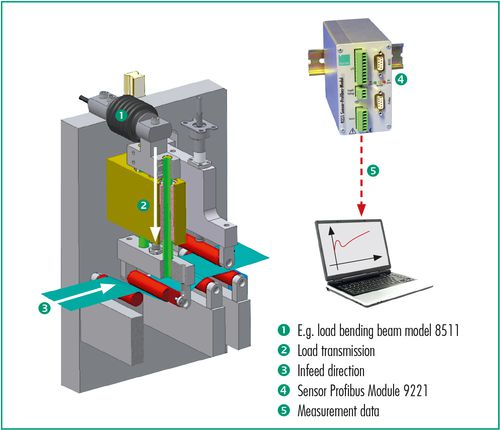

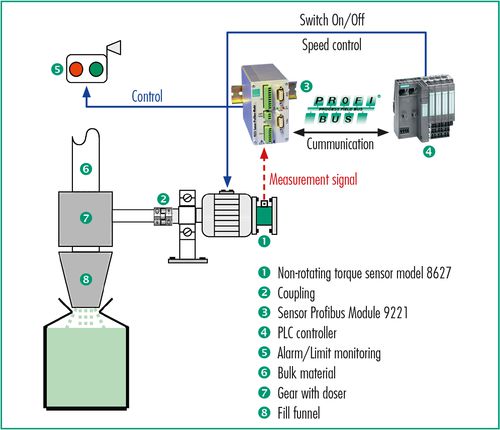

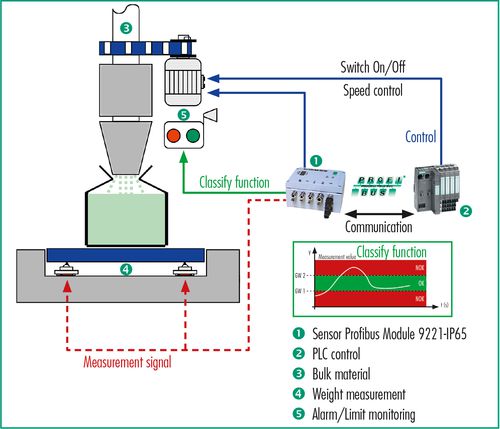

9221 Sensor PROFIBUS module

for force, pressure and torque measurement, simple configuration via RS232 interface, connectable via PROFIBUS DP, MIN / MAX memory, limits

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- For force, pressure or torque measurement with strain gauge sensors, potentiometric displacement and angle sensors or standard signals ± 10 V

- Resolution 16 bit, sample rate up to 1 kHz

- 2 free configurable inputs e.g. reset, tare, etc.

- Simple configuration via RS232 interface

- Networking via PROFIBUS DP up to 12 MBaud

- Mean value, MIN/MAX memory, set point values, zero compensation via PROFIBUS

- DPV1 mode for parameterizing and backup via PROFIBUS

- Potential-free input via differential amplifier

-

Product data

Model 9221 Measurement accuracy < 0.03 % F.S. Sample rate 1 kHz Type of sensor - Strain gauge

- Potentiometer

- Analog standard signals

Interfaces - RS232

- PROFIBUS

Indicator 3 LEDs (red, yellow, green) Sensor excitation Strain gauge:

- 2.5 V

- 5 V

- 10 V

Potentiometer:

- 2.5 V

- 5 V

- 10 V

Analog standard signal:

- 0 V … ± 10 V

Protection class IP20 / IP65 Supply voltage 20 ... 36 VDC

14 ... 26 VACSpecific characteristics - For force, pressure or torque measurement with strain gauge sensors, potentiometric displacement and angle sensors or standard signals ± 10 V

- Resolution 16 bit

- 2 free configurable inputs e.g. reset, tare, etc.

- Networking via PROFIBUS DP up to 12 MBaud

- Mean value, MIN/MAX memory, set point values, zero compensation via PROFIBUS

- DPV1 mode for parameterizing and backup via PROFIBUS

- Potential-free input via differential amplifier

-

Description

The newly developed sensor PROFIBUS module model 9221 is predestined for the integration of various analog sensor output signals into complex, net worked and peripheral automation structures. This module finds its fields of application in the industrial automation technology as well as the test rig technology based on its secure and reliable transfer mode, the fast transfer speed and its simple construction.

The inputs (e.g. PLC signal gauge) and outputs in addition to the external control allow a zero compensation by trigger via proximity switch or fast alerting on passing of set point values. Industrial type connection and mounting techniques enable the user the adaption and integration in the existing mechanical and electrical environment.

The excellent quality of measurement together with the high grade capture of mean values also enable the application in research and development.

The use of standardized PROFIBUS protocols makes the connection an easy task for the programmer.

Specific applications are found e.g. in:

- Complex gear and engine test rigs

- Weight definition in high-rack facilities

- Automotive industry

- Special equipment construction

- Packing industry

- Manufacturing technology

- Capture of various mechanical and physical values in test rigs

The universal sensor PROFIBUS module is well-suited for measurement of mechanical values such as e.g. force, torque, pressure, acceleration, displacement and angle. Strain gauge, potentiometric and standard signals may be captured and processed without problems. A powerful 16 bit A/D converter ensures a precise and fast processing of analog sensor signals.

The module itself features a stable and precise sensor excitation voltage. The calibration and configuration data are memorized on an EEPROM, protected against zero voltage.

The user friendly configuration software makes a simple conditioning of input signals and the setup of parameters on the module with regards to the PLC and PROFIBUS parameters possible. The version DPV1 enables the parameterization and backup function via PROFIBUS. Functions such as the arithmetical calculation of mean values, input signal filtering, zero adjustment, MIN/MAX memory and limits setpoint values can be realized with a speed of up to 12 MBaud via PROFIBUS.

Two potential-free and freely configurable digital inputs are available for the external PLC control (e.g. erase MIN/MAX memory, tare function). Two digital outputs can be defined as local limits switches for alerting functions.

The bus-sided control of the sensor lines on fractures or short-circuits and the galvanic separation between the PROFIBUS-ASIC and the PROFIBUS connector belong to the standard features.

The visualization of operating conditions such as bus connection, sensor-sided errors or active state of module are realized by three LEDs.

The DIN standard mounting rail enables an easy installation into the control cabinet.

-

Data Sheet & Downloads

-

Accessories

-

Application Examples

Related products

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.