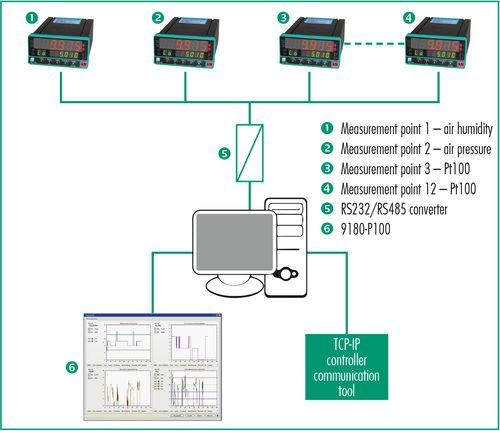

Monitoring atmospheric conditions

in the calibration laboratory

- Measurements transferred via RS232/RS485

- Min/Max value display

- Powerful software for recording and archiving measurement data

TASK

The requirement is to calibrate equipment in calibration laboratories under precisely defined environmental conditions. These rooms are air conditioned in order to ensure specific environmental conditions. Parameters such as temperature, air pressure and air humidity still need to be constantly monitored and logged, however. This is the job of a PC, which receives the relevant data via an RS232 interface.

SPECIFIC REQUIREMENT

Recording data on the PC from various sensors. Archiving measurement data for post-analysis.

SOLUTION

Digital indicators (model no. 9180) are used to record environmental readings at a total of 12 positions. The digital indicators transfer the recorded data to a converter via the built-in RS485 interface. The converter then converts the data into a form that can be read by the PC via its RS232 port. In the PC, the DigiVision software logs and visualizes this measurement data. DigiVision can process up to eight channels at once. To be able to capture 12 measurement points simultaneously requires the use of the controller communication tool.

This works as follows:

The user creates two device lists, each containing six devices. Then using the free TCP IP controller communication tool, the user creates a special macro. The tool loads the first of the two device lists and starts and stops the measurements. The tool then repeats this process with the second device list. The entire measurement routine can be repeated continuously under timer control.

Go to product 9180

Go to product DigiVision

Sectors

Downloads