Tension measurement

in paper manufacture processes

- High accuracy

- Three switched outputs

- Min/max measuring value collection

- A wide range of sensors can be connected

TASK

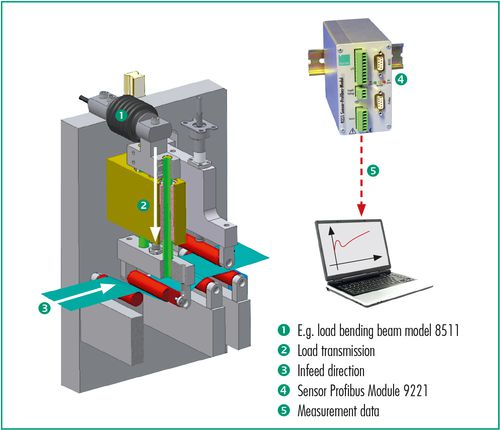

Set-up of a measurement actuator for the monitoring and visualization of a conveyer line while loading paper. For the interactive visualization and the integration in an universal Fieldbus environment, the Siemens Soft PLC should be implemented with a Fieldbus card (PROFIBUS DP). The visualization should comprise the entire measurement value progression and the top values (Max/Min).

SPECIFIC REQUIREMENT

No pleats or possible paper-rips can occur when rolling the paper. With recognition of a mistake, the drive must immediately be switched off in order to prevent possible impairments of the following production processes.

SOLUTION

For the force recording the load bending beam model 8511 and for monitoring the Sensor Profibus Module 9221 is implemented. The bending beam with measuring range 10 N is used as a representation, however a simple adaptation is very advantageous and easily accommodated for this delicate paper quality monitoring. A complication-less binding into the existing PROFIBUS control concept necessitates the use of our Sensor Profibus Module 9221. The easily integrated network with a selected baud rate up to 12 MBauds as well as shortest reaction times with MAX and MIN force infringement, (e.g. wrinkle effect through paper jam) predestine the integration of this module.

Go to product 9221

Go to product 8511

Sectors

Downloads