Testing the operation

of electric-bike drives

- High dynamic performance

- Torque/speed/power calculation

- Redundant power measurement

- Rugged design

- High measurement accuracy

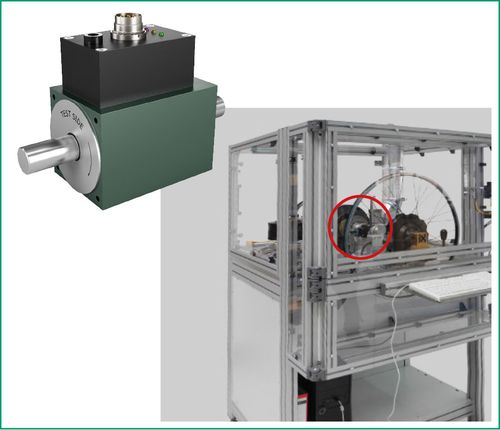

TASK

After assembly, the electric-bike drives need testing for correct operation. The speed lies in the range 1 to 254 1/min. The speed and torque must be measured (setpoint and actual values), with a continuous plausibility check. The process data must be logged and archived.

SPECIFIC REQUIREMENT

- High measurement accuracy

- Compact design

- Reliable speed measurement even at low speeds

- Range of fixing options to allow easy fitting of torque sensor

- Transfer of measurement data to PC via USB plus LabVIEW analysis of data

SOLUTION

An air-cooled magnetic particle brake was used as the test load. The setup also includes a manual quick-release unit and a manual connection unit for making electrical contact with the object under test. The precision torque-monitoring function is integrated in the safety circuit and used for the power calculation. The 8661 torque sensor with integral speed sensor was selected. The LabVIEW software is used for machine programming and for combined analysis and on-screen visualization of measurement results in the form of tables or graphs. The industrial PC is used for creating test programs and selecting the object under test.

Sectors

Downloads