-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

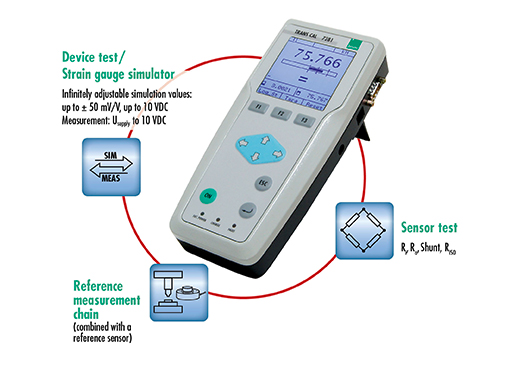

TRANS CAL 7281 Mobile high-precision calibrator and testing device for mechanical and electrical measurements

Device test, strain gauge simulator, sensor test, reference measurement chain

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- Supported sensors: Strain gauge/normalized signal ± 5V, ± 10 V, potentiometric sensors

- Device test: Strain gauge simulator up to ± 50 mV/V

- Easy adjustment through burster TEDS

- Excellent linearity with non-linearity < ± 0.001 %

- Storage of up to 16 measurement programs

- Data logger for up to 30.000 measurements

- Factory calibration certificate and / or German accredited DKD / DakkS calibration certificate optionally available for the instrument / entire measurement chain

-

Product data

Model 7281 Measurement accuracy < ± 0.001 % F.S. Sample rate 0.1 … 1200/s (DC)

0.1 … 2/s (AC)Type of sensor - Strain gauge

- Potentiometer

- Transmitter

- Sensors and devices with voltage output

Interfaces USB 2.0 Sensor excitation Strain gauge:

- DC: 2.5 V / 5 V (for 120 Ω only 2.5 V)

- AC: 2.5 Veff / 5 Veff (from 350 Ω)

Potentiometer:

- 5 VDC

Transmitter:

- 12 VDC ± 5 %

Protection class IP40 Supply voltage 10 ... 28 VDC Reference measurement device Yes Sensor test Yes Device test Yes Strain gauge simulator Yes Data logger Yes Electronic sensor data sheet Yes Connection type 4 / 6 wire connection Measurement programs 16 Specific characteristics - Device test: Strain gauge simulator up to ± 50 mV/V

- Easy adjustment through burster TEDS

- Storage of up to 16 measurement programs

- Data logger for up to 30.000 measurements

- Factory calibration certificate and / or German accredited DKD / DakkS calibration certificate optionally available for the instrument / entire measurement chain

-

Description

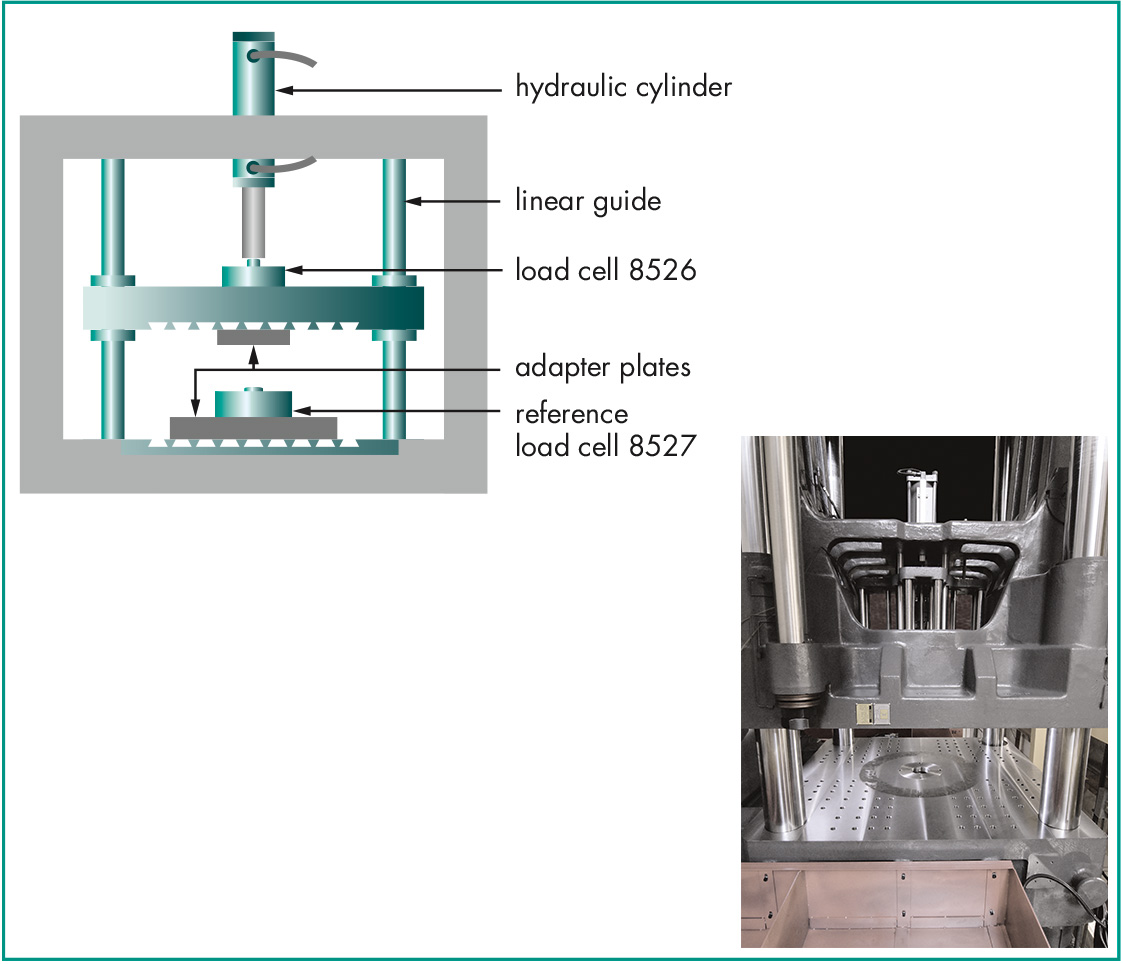

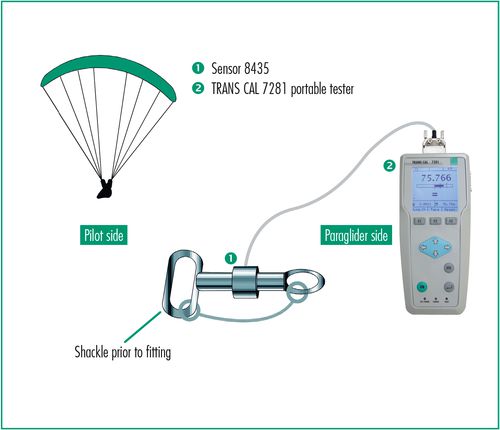

The multipurpose digital indicator TRANS CAL 7281 can be used wherever there is a need to perform high-precision, in-situ calibrations of sensing components used in equipment such as presses, torque tools or pressure-regulating systems. An optional factory calibration certificate or German-accredited DKD/DAkkS calibration certificate can be provided when the measurement device needs to be used as a reference. This provides a quick and cost-effective way of assessing a system with traceable documentation of measurement results.

If a reference measurement cannot be made because the sensor location is difficult to access, it is still possible to test the zero point, the input, output and isolation resistance as well as the calibrating offset of the fitted sensor. It is also possible to check the indicating device by measuring the excitation voltage and simulating the characteristic values (mV/V or V) of the sensor used.

The instrument is used in metrology institutes, calibration laboratories and in industry in the fields of quality assurance, facility commissioning and system monitoring.

Areas of use:

- Checking hydraulic presses

- Reference measurements in assembly lines

- Test of robotic pressing forces

- Calibrating test equipment

- Calibrating of high-precision measuring devices

The TRANS CAL 7281 can be fitted with standard or rechargeable batteries for portable use or can run from an external power supply. Combined with a reference sensor the testing device provides a high-precision reference measurement chain e.g. for force measurements, but is also ideal for service engineers as a tool for locating faults in device or sensors.

The choice of sensors includes strain gauge, normalizedsignal ± 5 V / ± 10 V and potentiometric sensors. The LCD graphics display shows the live measurement value and the corresponding bar indicator. It also supports display functions such as data-logger, tared value in % and upper/lower limit for the comparator with simultaneous indicator (< = >) of the evaluation result.

For routine testing and also fault-locating tasks, the tester makes it really simple to measure isolation resistances and input/output resistances. The equipment test function is a quick and easy way to verify that the display device complies with the characteristic value, offering strain-gage simulation of up to ± 50 mV/V or output of a normalized signal of up to 10 V. German-accredited DKD/DAkkS calibration certificates or factory calibration certificates are optionally available. The DigiCal configuration and data-acquisition software provides useful display and reporting functions.

-

Data Sheet & Downloads

-

Accessories

-

Videos

Please accept marketing-cookies to watch this video.Motek exhibition video burster 2015

Please accept marketing-cookies to watch this video.burster Calibration to go Control 2015

-

Application Examples

Related products

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.