-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

8710, 8711 Potentiometric displacement sensors

For direct and accurate measurement of mechanical displacements, lateral force-free drive, very long life duration, high displacement speed

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- Measurement ranges 0 ... 25 mm to 0 ... 150 mm

- Non-linearity: max. ± 0.05 %

- Service life: 108 movements

- Displacement speed: up to 10 m/s

- Drive free of lateral forces caused by ball joint coupling

- Integrated cable or plug connection

-

Product data

Model 8710, 8711 Principle Potentiometric Measuring range 0 … 25 mm

0 … 50 mm

0 … 75 mm

0 … 100 mm

0 … 150 mmSignal output Depending on excitation voltage Protection class IP40 Range of operating temperature -30 ... +100 °C Supply voltage Depending on measuring range Electrical connection 8710

5 pins plug connection8711

Integrated connection cable 1 m

Integrated connection cable 3 m

Integrated connection cable 5 mReturn spring No Specific characteristics - Service life: 108 movements

- Displacement speed: up to 10 m/s

- Drive free of lateral forces caused by ball joint coupling

-

Description

Displacement sensors models 8710 and 8711 with resistance tracks made of conductive plastic material are designed for a direct and accurate measuring of mechanical displacements. A special ball joint coupling is mountable on both ends of the driving rod. Because of this the sensor may be used free of clearance or lateral forces also with angular or parallel misalignment between sensor and measuring device.

A special multi-fingered slider provides a good electrical contact also at high adjustment speeds or vibrations.

Areas of application are:

- Electromagnets

- Switch and button deflections

- Pneumatic cylinders

- Press-fits (longitudinal press-fits)

- Hydraulic cylinders

- Measurements of deformation and bending

- Length tolerances

- Feeding paths

Due to the technology employed in potentiometric displacement sensors, they always operate with a sliding contact system. Special processes are applied to give the resistance tracks low friction, low tendency to stick/slip, resistance to abrasion and long-term stability.

The driving rods are guided in long-life, low-friction sliding bearings with close tolerances; this results in highly precise measurements. Lateral forces reduce the service life and can be avoided by using, for instance, ball joint couplings, included in the burster product range.

Due to the pump effect, the driving rod has double sliding bearings.

Mounting

The sensor is mounted at the left and right longitudinal slot by four mounting angles.

These slots (W = 2.2 mm, D = 1.6 mm) are closed at the side of the electrical connector.

-

Data Sheet & Downloads

-

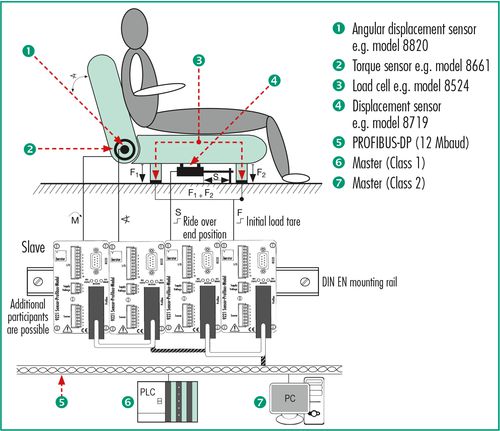

Application Examples

Related products

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.