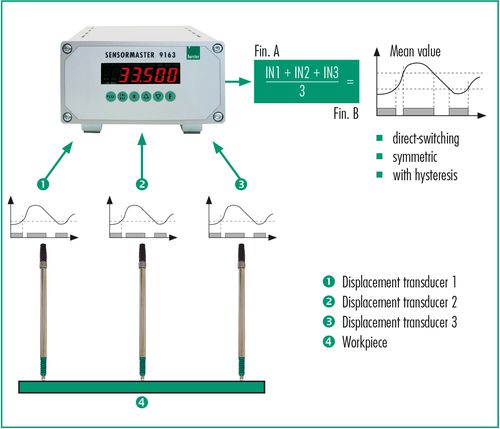

Testing for flatness

on a workpiece

- High-speed switching outputs

- Mathematical function

- High sampling rate

- Measured values can be transferred via PROFIBUS, RS232, USB or analog output

TASK

The flatness of a workpiece needs to be measured. To do this, measurements must be taken at three points to determine whether the workpiece is within tolerance. The results from these measurement points are compared using an electronic analysis unit. If the workpiece surface is found to be out of tolerance, the unit must immediately indicate the point at which the maxima have been exceeded. In addition, a visual display is required to make it easier to identify such workpieces.

SPECIFIC REQUIREMENT

High sampling rate, high-speed switching of limits.

SOLUTION

burster displacement transducers are used at the three measurement points. All displacement transducers from the burster range are suitable for use here. A SENSORMASTER 9163, with two main inputs, performs the analysis. The unit uses the two mathematical functions "Fin.A" and "Fin.B" to determine the mean values. To do this, the user assigns each of the inputs and the function "Fin.B" to a limit switch. These switches are configured as a direct-switching, symmetric alarm with hysteresis for minimum and maximum values. The process-value display can be configured to show a change in display colour as soon as one of the limit switches is active. In this case, the limit indicators show which measurement value is out of tolerance. Using the RS232 option with the 9163-P100 measurement data software, a PC can be employed to log and archive the measurements. This process can be automated by the controller communication tool included in the software.

Go to product SENSORMASTER 9163

Sectors

Downloads