-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

- burster

- Measure & Test Devices

- Microohm- and milliohmmeter

- RESISTOMAT® 2329

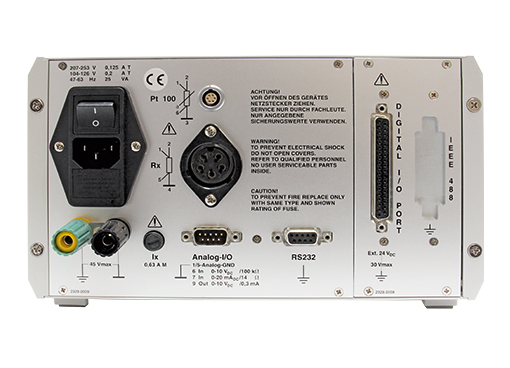

RESISTOMAT® 2329 for fast resistance measurement in automated processes

Up to 50 measurements and evaluations per second, RS232 and PLC interface standard (IEEE488 and USB option), resolution up to 10 µΩ, accuracy 0.03 % Rdg.

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- Measurement range from 200 mΩ ... 200 kΩ

- Resolution up to 10 μΩ

- Measurement accuracy 0.03 % Rdg.

- Automatic measurement range selection

- Up to 50 measurements and evaluations per second

- Temperature compensation for all materials

- Thermovoltage compensation

- Dry-circuit measurement in accordance with DIN IEC 512

- Data logger for 20 000 measurement values

- RS232 and PLC interface standard (IEEE488, USB and Ethernet option)

-

Product data

Model 2329 Measuring range 200.00 mΩ

2.0000 Ω

20.000 Ω

200.00 Ω

2.0000 kΩ

20.000 kΩ

200.00 kΩResolution 10 μΩ

100 μΩ

1 mΩ

10 mΩ

100 mΩ

1 Ω

10 ΩMeasurement accuracy ≤ 0.03 % rdg. Measurement display 20 000 counts Automatic temperature compensation Yes Comparator Yes Interfaces - RS232

- PLC

- IEEE488 (option)

- USB (option)

- Ethernet (option)

Specific characteristics - Automatic measurement range selection

- Up to 50 measurements and evaluations per second

- Temperature compensation for all materials

- Thermovoltage compensation

- Dry-circuit measurement in accordance with DIN IEC 512

- Data logger for 20 000 measurement values

-

Description

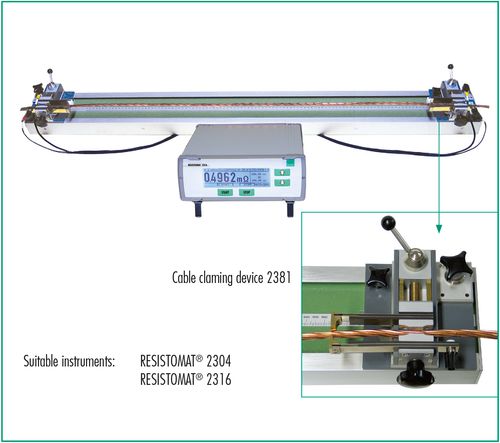

The RESISTOMAT® model 2329 is particularly suitable for fast measurements of low resistances in automated processes. Up to 50 measurements per second can easily be performed. The device complies with the latest CE guidelines and is designed for laboratory use as well as heavy-duty industrial applications.

A 2-fold and 4-fold comparator with switching outputs has been included for classifi cation and selection; this feature is particularly useful for serial tests.

One special application involves the measurement of contact resistances (dry-circuit measurement); the load voltage in this case is limited to 20 mV in order to prevent fritting (DIN IEC 512). The RS232 (standard) and IEEE488, USB and Ethernet (option) computer interfaces allow the set-up of fully automatic testing stations. The PLC interface allows easy integration into your production process control.

Typical applications are resistance and conductivity measurements on:- Fuses

- Airbag triggers

- Coils for the automobile industry and electrical engineering

- Plug-in contacts and switches

- Commutator welded joints

- Meter samples in cable manufacture

- Circuit-board conductors etc.

The device operates on the basis of proven 4-wire technology which corrects any incoming line or contact resistances.

The measurement lines are checked by an integrated cable rupture monitor. Needless to say, the functions include temperature compensation for various test substances such as copper, brass, tungsten etc. Temperatures are measured by a Pt 100 sensor or infrared sensor (pyrometer) with analog outputs or any temperature transmitter e.g. thermocouple.

For measuring test objects with low inductances, a special measurement input protection was developed to prevent voltage peaks from damaging the device when test objects are disconnected.If objects need to be tested for several different parameters by an automatic measurement system, you can store up to 32 device settings such as measurement ranges, limiting values, temperature coeffi cients etc. These settings are called up via a bit pattern (5 bits). Naturally, all device settings can also be made via the RS232 (standard) or IEEE488, USB and Ethernet interfaces (option).

The integrated data logger can be used during serial measurements to store up to 20 000 measurement values which can be divided into 32 individual blocks. A digital filter is available for preselecting the measurement values to be stored. The evaluation menu of the stochastic data logger displays the maximum, minimum and average values as well as the standard deviation.

-

Data Sheet & Downloads

Data sheetOperation manualSoftwareFurther info -

Accessories

-

Application Examples

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.