-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

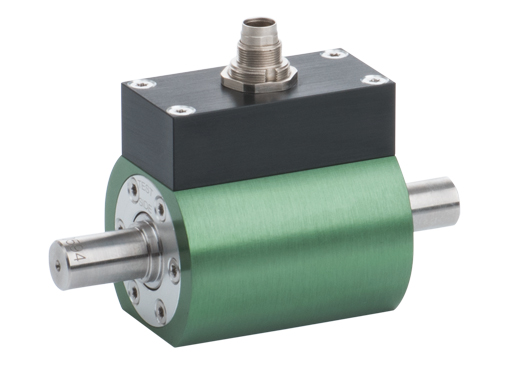

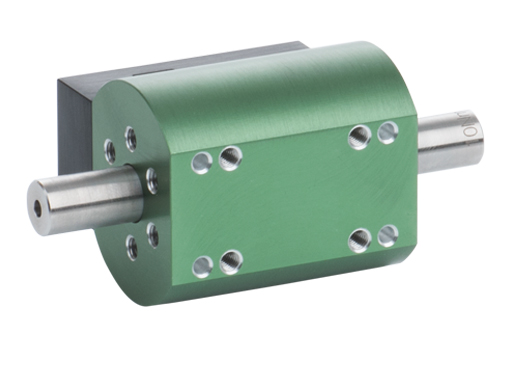

8625 Precision torque sensor

Robust, reliable, easy handling, highly accurate, extremely compact design, for static and quasi-static measurement (non-rotating)

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- Measurement ranges from 0 ... 0.01 N·m to 0 ... 200 N·m

- Linearity error from ≤ 0.05 % F.S.

- Output signal ±10 V / USB / mV/V

- Tare function, filter and average values configurable

-

Product data

Model 8625 Principle Non-rotating Measuring range 0 … ± 0.01 N·m

0 … ± 0.02 N·m

0 … ± 0.05 N·m

0 … ± 0.1 N·m

0 … ± 0.2 N·m

0 … ± 0.5 N·m

0 … ± 1 N·m

0 … ± 2 N·m

0 … ± 5 N·m

0 … ± 10 N·m

0 … ± 20 N·m

0 … ± 50 N·m

0 … ± 100 N·m

0 … ± 200 N·mSignal output 0 ... ±10 V incl. configuration USB

0 ... ±10 V incl. USB configuring and measuring USB

Standardized output signal (mV/V)

Standardized output signal (mV/V) with TEDSMechanical connection Round shafts

Mounted flange adapter

Mounted bracketElectrical connection 7 pins, Micro-USB (Option) Protection class IP40 Range of operating temperature -20 °C ... +80 °C

with integrated amplifier/USB

-20 °C ... +60 °CSpecific characteristics - Standardized output signal

- Extremely compact design

-

Description

This high precision torque sensor is designed for both static and dynamic measurements on non-rotating applications. It is particularly suitable for torque measurements on, for instance, extremely small electrical actuating drives and micro-mechanical actuator elements, or for measuring reaction torques e.g. on micro-motors.

The high accuracy of measurement also makes this sensor ideal for use as a reference in many fields of industrial manufacture as well as laboratory research and development projects. Not containing any rotating parts, it requires no maintenance if properly used.

The strain-gage based sensor’s modular design allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ±10 V that is proportional to the torque. The sensor can be configured via the micro-USB interface, providing access to, for example, a filter frequency setting, averaging, and a tare function. Measurements via USB in addition to the voltage output are available with the USB measurement option. The sensor comes with the DigiVision software for performing measurements and data archiving, with drivers additionally available e.g. for LabVIEW. Integration into custom software is possible via DLL.

The burster TEDS option (electronic data sheet, memory chip with sensor-specific data) allows rapid configuration of compatible evaluation units (instrumentation amplifier, indicator, ...).

-

Data Sheet & Downloads

-

Accessories

-

Videos

Please accept marketing-cookies to watch this video.Torque Sensors: Made in Germany - Made by burster

Related products

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.